[ad_1]

Devised to make all-electric flight a reality, Evolito is pioneering the field of electric air transport by offering streamlined and direct-drive electric propulsion and battery solutions. In a Q&A session, Evolito CEO Chris Harris will reveal more.

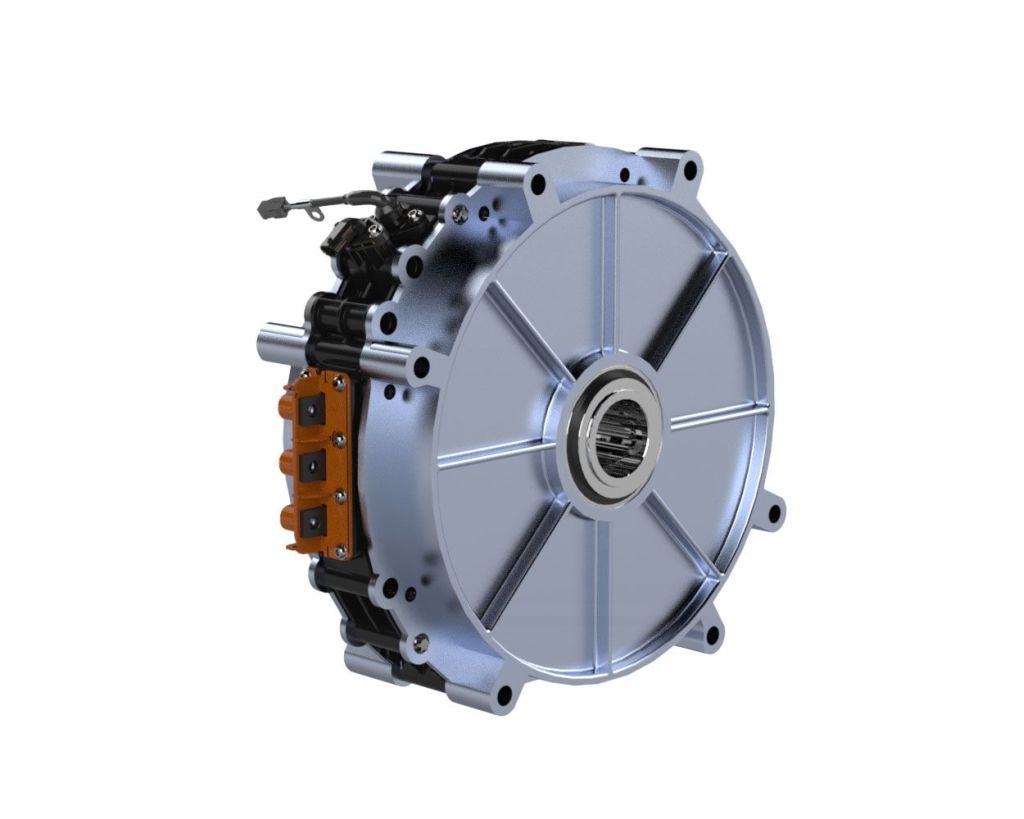

Evolito offers high-performance, lightweight axial-flux motors and controllers that are smaller, lighter and safer than any competing electric propulsion technology. Evolito’s products enable a variety of new electric propulsion applications, helping to accelerate the aerospace industry’s move toward net zero.

Q) First, tell me about your history and role at Evolito.

When I joined YASA in 2011, I had no idea that the automotive sector would be a leading opportunity for our technology. We know the benefits that attract automotive OEMs – YASA’s world class power to weight ratio – will be even more valuable in aerospace applications. Before YASA was acquired by Mercedes-Benz, we spun off YASA’s aerospace division as a new company – Evolito.

I want to be clear: this is not about transplanting automotive technology into aerospace, we are using our experience in automotive electrification and serial production and already robust and standard-designed technology. It’s a very disruptive and innovative approach to aerospace. We aim to provide best-in-class products that meet all aerospace safety and regulatory requirements, but at the price and volume demanded by the automotive industry.

I see my role as developing the strategy, technology and team to meet the requirements of the emerging aerospace electrical market. This is not set in stone; It’s in constant flux, so being efficient is key. My goal is to deliver on-demand solutions to OEMs and air handlers and be able to scale to size when the market demands it.

Q) How far along are you on the road to making electric airplanes a reality?

Regarding electric flight’s path to mainstream commercialization, we see an emerging market for both hybrid and pure electric aircraft, but we believe they will grow at different rates. There are many challenges to overcome before the eVTOL market becomes mainstream. Barriers to entry for hybrid aircraft are lower than eVTOL. As a result, we are developing products that cater to both the hybrid and pure electric aircraft markets.

The main products we are developing are e-motors based on our proprietary axial flow motor technology and motor control units (MCUs) – the power electronics between the power source and the e-motor. We are also developing integrated propulsion solutions incorporating our e-motors and MCUs.

Combining what we have learned from Yasa for sound production design and this with the aerospace experience developed within the Evolito team, we have developed e-motors and MCUs that meet all the important aerospace requirements and can be quickly scaled up. Market demand is growing.

We have access to all of YASA’s manufacturing IP, patents, processes and know-how to fit our e-motors production line at the required quality levels in production to meet aerospace requirements.

We also have strong and growing business relationships with general aviation OEMs, airfreighters and emerging EVoil companies, developing the necessary design and production organization to certify our products.

Later this year we expect to have the first samples of both our next generation axial flux e-motors and MCUs in use at Evolito for internal testing and trial use at customer sites. We also expect to see our e-motors and MCUs in test aircraft within the next two years. We are approaching the market with the same approach that I have already taken with automotive electrification at YASA.

Q) Tell me about the Electrofly acquisition at the end of last year?

We acquired Electroflight because it gives Evolito the ability to understand and solve our customers’ challenges at a complete system level, including motor, MCU and battery. There are a number of challenges that need to be met from a battery perspective to enable the growth of the all-electric aircraft market. This is not just about cell technology – infrastructure challenges and ecosystem challenges need to be addressed as well. Following this acquisition, our vision is to provide complete incentive systems. We know that battery systems will influence the electrification market in the aerospace sector. Electroflight gives us the ability to solve some fundamental industry problems.

Q) What kind of motor and battery power performance requirements are met by today’s airfoils?

Safety and electrical power to weight ratio (EPU) are the biggest drivers of customer demand. Best-in-class competitor power-to-weight ratios now seem to be around 7kW/kg, but we are aiming to deliver 13kW/kg in our first products. Our Axial-Flux technology has a clear roadmap for higher power to weight ratios in the future.

The ability to meet aerospace safety and quality standards at a competitive price while simultaneously delivering superior performance at the system level will be critical to accelerating the electrification of the aerospace sector. We understand these challenges and believe our proprietary e-motor technology and systems capabilities put us in a very strong position to meet these new customer requirements.

Q) Do you get healthy R&D funding and support from organizations like the Aerospace Technology Institute (ATI)?

We have great support from ATI. For example, we received a grant to help us develop stand-alone and integrated products with core e-motor and MCU technologies for the general aviation and emerging EV vehicle markets.

ATI is a great organization and vital to enabling the development and delivery of innovative technology in the UK aerospace sector. That said, it currently focuses on topics like hydrogen, and perhaps if it broadens that focus, it could have more impact.

The UK is ideally placed to be a leading international hub aiming to deliver the innovative and disruptive technology required for widespread adoption of electric flight. We have all the ingredients here and if government support can be focused more broadly to meet the broader industry needs, this is a huge market opportunity.

Q) When do you foresee the adoption of short-term electric aircraft reaching its destination?

We think the hybridization of fixed-wing and electric convertibles will be early market opportunities for electrification. This is similar to the path electrification took in the automotive market 10 years ago. We expect to see early hybrid opportunities where an electric motor component will be used to enable quieter take-offs and landings and help reduce emissions in cities.

One of the main challenges remains the batteries. Due to the limitations of current battery technology, an eVTOL aircraft can only launch from a range of 20-30 miles. This will likely limit market adoption. A range of 100-150 miles would be needed to make the first cross-country routes viable, and battery life would be a critical issue for the economics of such aircraft. In addition, there is a need to develop infrastructure to support these aircraft. Only when these issues are resolved will we see significant growth in the market for eVitols.

Q) What type of motor and battery technology is gaining attention in the aerospace industry?

We believe Evolito’s proprietary Axial Flux e-motor technology is ideally suited for aerospace applications because it provides significantly higher power and torque densities than conventional radial flux motors on the market today.

One of the areas we believe needs to be addressed by suppliers in order to reach its forecasted growth potential in the Evitol market is the ability to balance competitive pricing. We believe Evolito is well-positioned to meet these new requirements for the aerospace industry by leveraging the experience gained through volume in the automotive market.

Q) Much is being done to reduce the weight of materials and components in aircraft, but engines and batteries are still heavy?

Evolito e-motors and EPUs offer a world-beating power to weight ratio and this is the biggest driver of demand from customers. Our best competitors in the segment are currently offering 7kW/kg, where we offer 13kW/kg. This is important because customers want assurance that a supplier will continue to meet their changing requirements as the market matures and evolves.

Regarding batteries, Electroflight offers Evolito to solve the entire industry’s challenges, including e-motor, MCU and battery. This is not just about cell technology – infrastructure challenges and ecosystem challenges need to be addressed as well.

Q) What differentiates and sets you apart from the competition?

Our core axial-flux motor technology is highly differentiated, offers a market-leading power-to-weight ratio and delivers system-level benefits to our customers. Proven in aviation applications such as the award-winning ACCEL project and automotive applications as a special launch pad from the world’s most sought-after major automotive OEMs.

Our acquisition of Electrofly last year means we now have additional capabilities in battery design and manufacturing. We can solve customer problems by providing best-in-class complete power generation solutions. Our team’s experience in designing, manufacturing and future-proofing electrification technology makes us unique in this industry.

Q) Finally, where do you see the biggest business challenge in 2023?

We have a clear strategy and product roadmap in both the general aviation and eVTOL markets, so 2023 will deliver the first samples to our customers and certified EPUs, engines and MCUs. Our growth plans are extensive and we have secured funding to support those plans.

Our biggest challenge this year is recruiting the top quality talent we need to grow the business, but we’re off to a great start in January and we’re confident we’ll be able to fulfill our ambitious business goals by filling the positions we need with highly competitive candidates. .

We started with five employees and will have over 130 employees by July 2021. About 60% of our headcount comes from the aerospace industry and 30% from automotive. We believe the combination of proven automotive electrification experience and deep aerospace sector knowledge is a very powerful combination to bring to this high growth market.

[ad_2]

Source link