[ad_1]

Each electronic circuit you are considering has at least one printed circuit board (PCB) that connects the various components that make up the home and make the device work. Circuit boards are often invisible to the end users and are the basis of the world in which they live, moving smartphones, automobiles, microwave ovens, garage doors, and the entire connected world.

Thus, the global PCB market is big business, with industry expected to grow from $ 60 billion by 2020 to $ 75 billion by 2027. And Celluus, based in Germany, has an automated platform that covers the entire circuit board design. Process, from ID to PCB.

To accelerate its “automation of electronics design”, Celus announced today that it has raised 25 million euros ($ 25.6 million) in a series of grants.

So what is the extent of the problem that Celsius is planning to solve?

Lack of organs

The PCB from scratch design engineer should come up with the concept of the original circuit diagram based on the components needed to light the final product, transistors, resistors, capacitors, fuses, sensors, batteries, diodes and everything else. The problem is that there can be millions of different parts to choose from in different sizes and specifications from thousands of manufacturers. So choosing the right parts for the job at the right price and availability can be an incredibly laborious process, involving thousands of courses from the company that work together to examine and identify the right parts.

Only then do engineers begin to draw the correct circuit diagrams to bring all the parts together, which they finally find on the PCB. But if you think this is the end of the process, you are wrong. If certain components (such as chips) are difficult to purchase, especially in the post-epidemic supply chain, companies often have to redesign their circuit board, which means engineers have to redesign their design.

“Replacing a non-existent part with the same component is theoretically possible, but this will result in a time-consuming and expensive electronic circuit and PCB design,” Celia CEO and co-founder Tobia Pohl told Tech Crunch. “Such a redesign process takes place in minutes at the Celluan automation platform.”

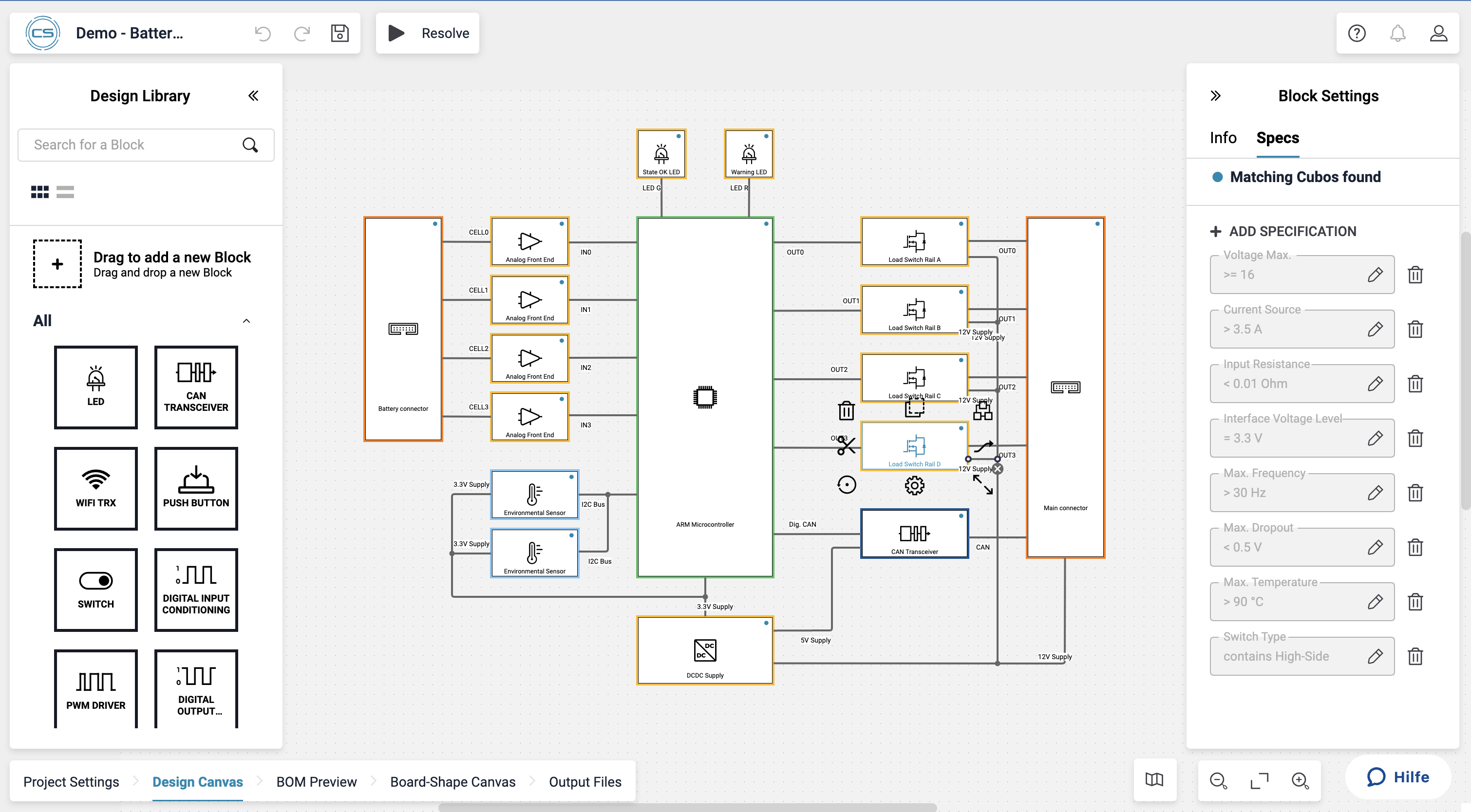

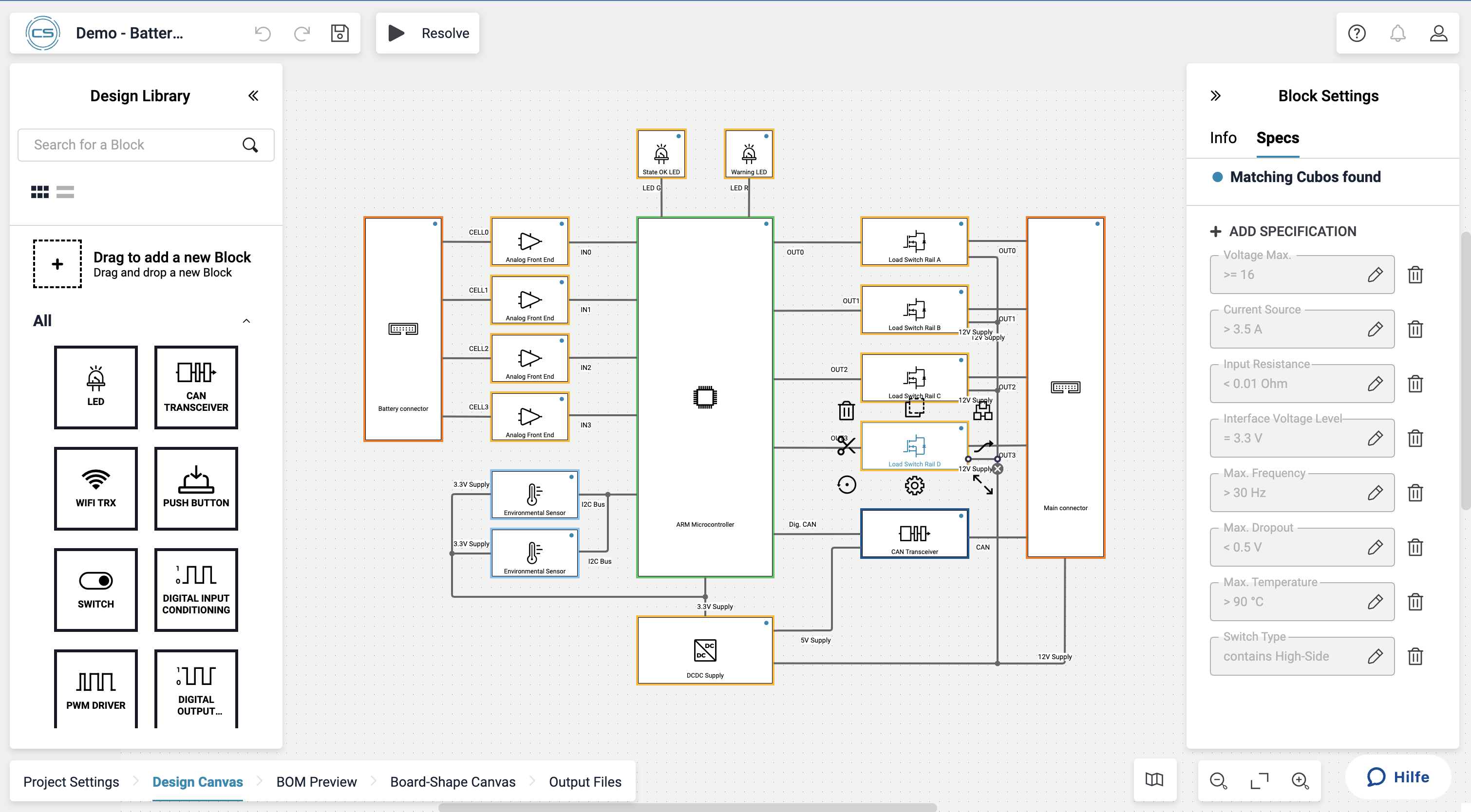

Celsius has added its own special automation system to the mix and has built a platform for information from electronics manufacturers. In fact, Selus automates many of the manual processes involved in circuit board design, including creating designs – a conceptual drawing of how parts connect – and a PCB “floor plan” that shows where each component is placed on the circuit board.

“Our design canvas provides the drawing board to capture the product concept, and then automatically generates the circuit design,” Paul said. “The components are selected according to the requirements and the automation generates even the first PCB. Engineers save a lot of time during this time, which means they can experiment, try different things and create.

Therefore, Cellulose users simply define their requirements, which are automatically linked to the class library to find the best solution. And this is where Cellular tries to differentiate itself from other AI-powered PCB players – giving priority to component selection and graphic design and making it all available in a user-friendly GUI.

Celluus in action. Image thanks Cellulose

AI is used not only in the design of new circuit boards, but also in the process of extracting data from existing unstructured data sources – for example, when engineers upload schematics and PCB layouts to cellulose, algorithms interpret predictions from data in these files.

“Normally people had to eat and translate a lot of files used in circuit board design but AI can digitize that kind of data and translate it into machine learning,” Pohal added.

It should be noted that Cellular can be used as a stand-alone system or integrated with the existing IT environment to enable basic AIA smartphones to work with industry-leading electronic design automation (EDA) equipment.

Time

All of this ultimately saves precious time, in a world where there are no engineers capable of moving invaluable goods. And as international events such as epidemics and wars exacerbate this issue, Celus is well on its way to benefiting the time-bound circuit board engineers by re-inventing their products by giving them the ability to redesign their products.

“The CVD-19 epidemic has caused an unprecedented shortage of body parts in the industry – obsolete and supply chain issues are always a concern. They are forced to change, ”Paul continued. “Our automation will handle that redesign test in minutes and make it a viable option for product redesign.”

A.D. Founded in 2018 in Munich, Celus raised 5. 5.4 million over a four-year period. During that time, however, it accumulated ስም 3.4 billion worth of customers, including Siemens and Vishman, German heating and cooling systems.

The Seleus series is hosted by Earlybird Venture Capital and includes DI Capital, SpeedInvest, Plug and Play and several angel investors, including former Rolls-Royce CEO Sir John Rose and Google cottage hardware development assistant Paul Gojenola. He said the company plans to open a new office in the US to “put it in the heart of the electronics industry” with the new cash injection.

“We want to get every electronics designer out there, which will allow them to focus more on creativity and innovation, but our software will reduce the boring and time consuming work you have experienced in the past,” he said.

[ad_2]

Source link