[ad_1]

As pressure grows on companies to reduce dependence on gas and oil, established processes are being questioned even at industrial scale, giving the technology an opportunity to enter. Sepure seeks to replace gas-based complex oils with membrane engineering. The nanometer scale, and its approach, has attracted $12 million in a new funding round.

All oils must be extracted and purified from their source, which may be seeds, fibers or other organic matter. Of course you can crush an olive and extract a lot of oil, but not everywhere; To do this, the pulp is immersed in a solvent such as acetone or hexane, which extracts the remaining oil. The resulting mixture is usually heated with natural gas or oil and the solvent and oil are separated.

This fuel-based process has lasted for decades, as the high heat required precludes the use of solar or wind heat as a heat source.

An alternative has been seen many years ago in the field of water filtration, which has long used a filtration process to separate H2O from contaminants. Membranes can be engineered to allow certain substances in, while others are blocked, such as water molecules, but not large organics. This approach has long dominated the water industry, because it’s cheap, simple, and uses less energy (see “reverse osmosis” on the label).

Sepur founder and CEO Mohammad Farahani said climate change and gas price pressures (not to mention cost savings) have led them to consider other coatings as an alternative. For example, DeVigas developed a membrane that separates hydrogen from carbon dioxide and developed Membrane to remove heavy metals from water. But unlike many chemical precursors like essential oils and other molecules, water is not a very powerful substance.

“It took a long time to find a good solution for water, and basically every company makes a coating that focuses on water,” Farahani said. “It was probably only 10 years ago that people started researching chemical-resistant coatings. We think we’re in the same place as when water coverage started 40 years ago – it’s starting to be implemented basically everywhere.

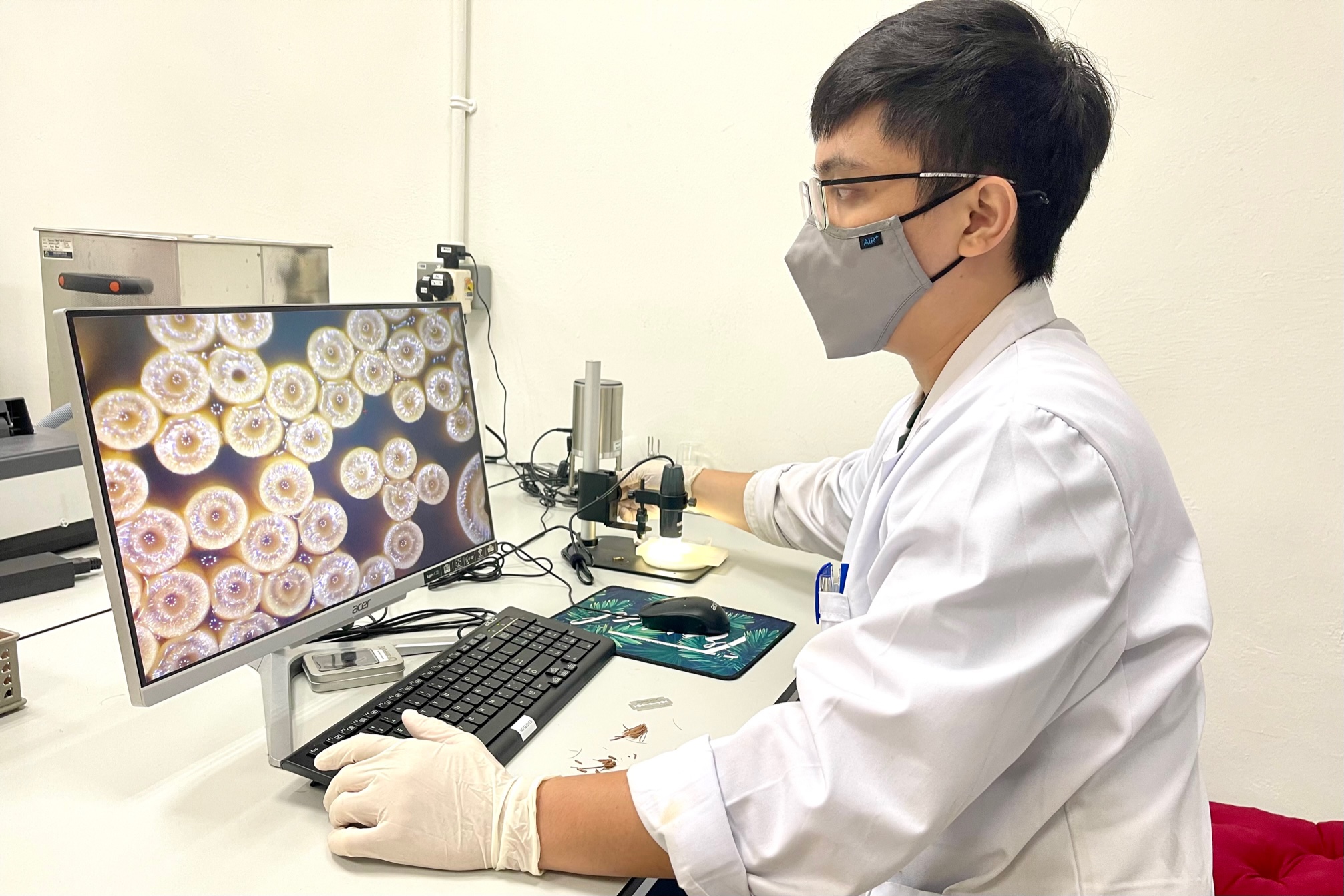

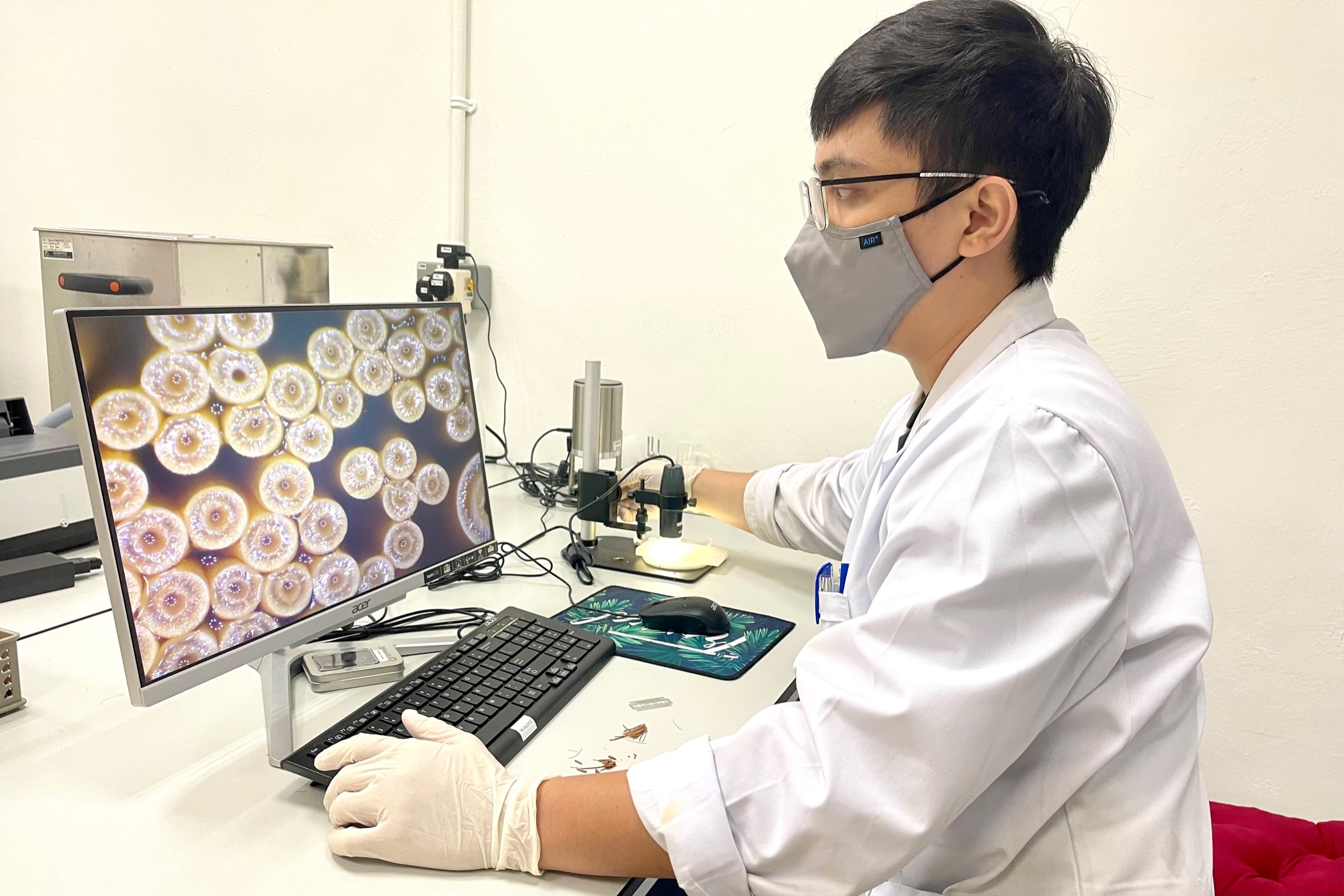

A computer shows a cross-section of Sepure nanofilter tubes.

Sepure makes what it calls a hollow fiber nanofilter, which is exactly what it sounds like: a hollow polymer fiber with a surface engineered at the nanometer scale to allow certain molecules to pass through. Make a bundle together and stick it in a tube and push liquid through the tube to filter. Although the coating does not 100% separate the two substances, it greatly reduces the level of splashing. The concept is not new, and is actually used in the membrane industry, but where the difference of Sepure is in its strength and packaging.

“Strong solvents can easily dissolve polymers – you have to make polymeric membranes using Liquids, but then they need Resistance Liquids. That’s a challenge and a lot of research has been done to get there,” Farahani said. “The beauty of what we’ve done is create a fiber that can withstand harsh chemicals, high temperatures and high pressures.”

In those categories, water and gas aren’t as demanding, so they get the most attention, but now there’s a version that separates oils from solvents or other valuable molecules in similarly difficult mixtures. That said, in any industry there are applications that still use stripping because of the fragility of the old coating processes – and there are many. Segregation processes account for a significant share of global energy use and emissions.

Sepur has a competitor in Germany’s Evonik, which makes a similar product. But while this earlier version of the technique was good for high-margin products like the pharmaceutical industry, it was too slow and bulky to use in high-volume, low-margin processes like edible oil production.

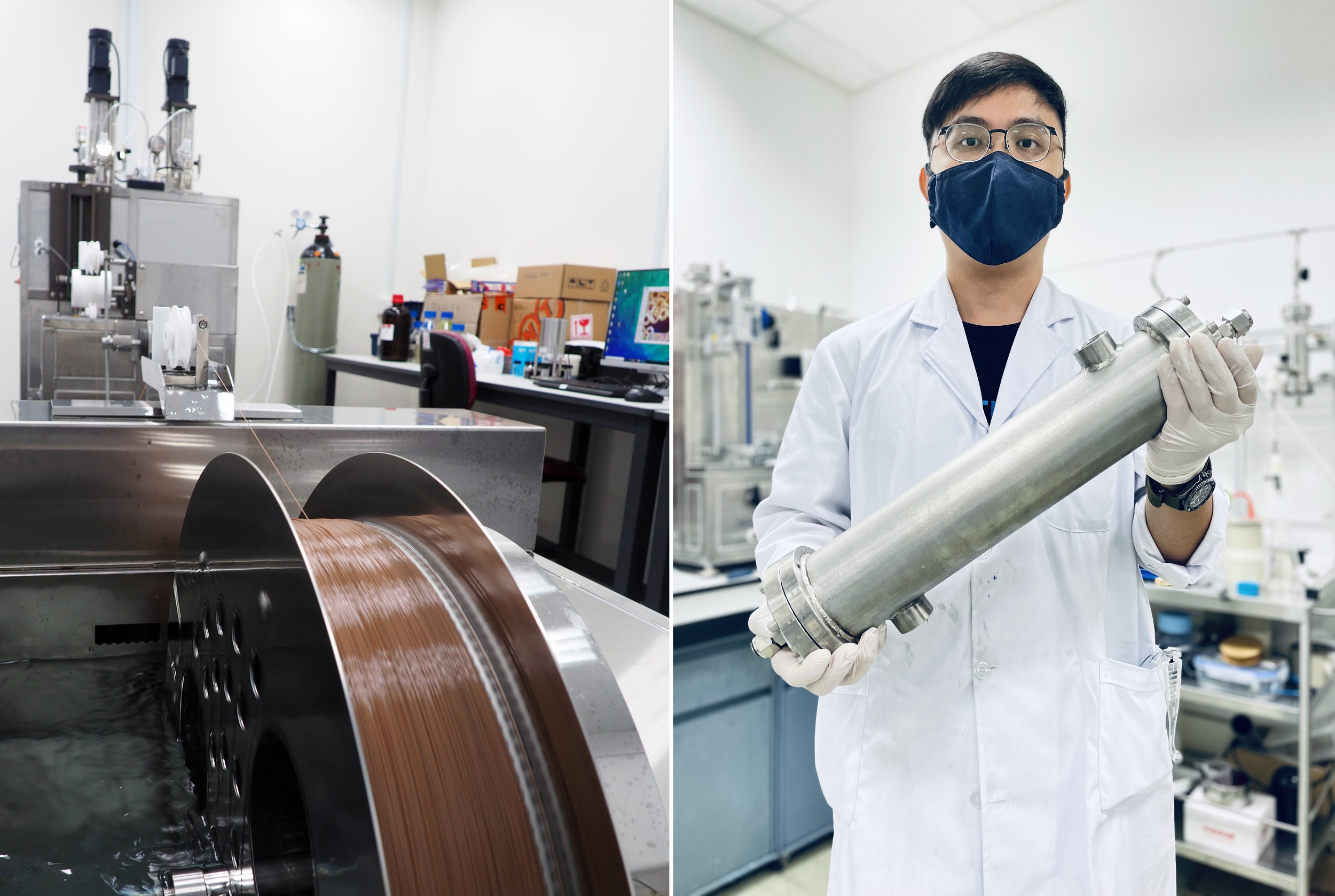

A hollow fiber nanotube is created in the lab, and a small version of the final filter appears.

Filters come in standard sizes: pipe 4 in diameter and 40 inches long. Sepur claims it puts five times the coverage in that space, improving efficiency and reducing costs: it can push five times more material with the same number of pipes or filter the same amount in much less space. And this is without taking into account the increased pressure and other combination factors.

Overall, with these findings and the reduction in oil-based heating, Farahani estimates that the cost of producing 100,000 tons of oil per year (for example) will drop from $7.5 million to $2.5 million. And apparently the filter fibers, once exhausted, can be reused after a few years of use to create flame-retardant fabrics.

The $12 million A round was led by SOSV, with participation from Anji Microelectronics, Real Tech Fund, Seed Capital, EPS Ventures and others. The company previously raised $2.5 million in 2019.

The funds will be used to complete the construction of the first refinery in Singapore.

“Once we start implementing our technology solutions at customer sites, we will quickly reach maximum capacity. Our team is working on expansion plans in anticipation of growing demand for our modules,” said Farahadi.

[ad_2]

Source link