[ad_1]

Patient time They go to the clinic for an ultrasound of their abdomen and lie on a sheet of paper taped to the exam table. A clinician will spread a thick goo over their abdomen, then attach a small probe and send acoustic waves into the patient’s body. These waves are picked up by their soft tissues and body fluids, they are returned to the examination and translated into a 2D image. As the probe moves across the person’s abdomen, a blurry black-and-white image appears on the screen for the doctor to read.

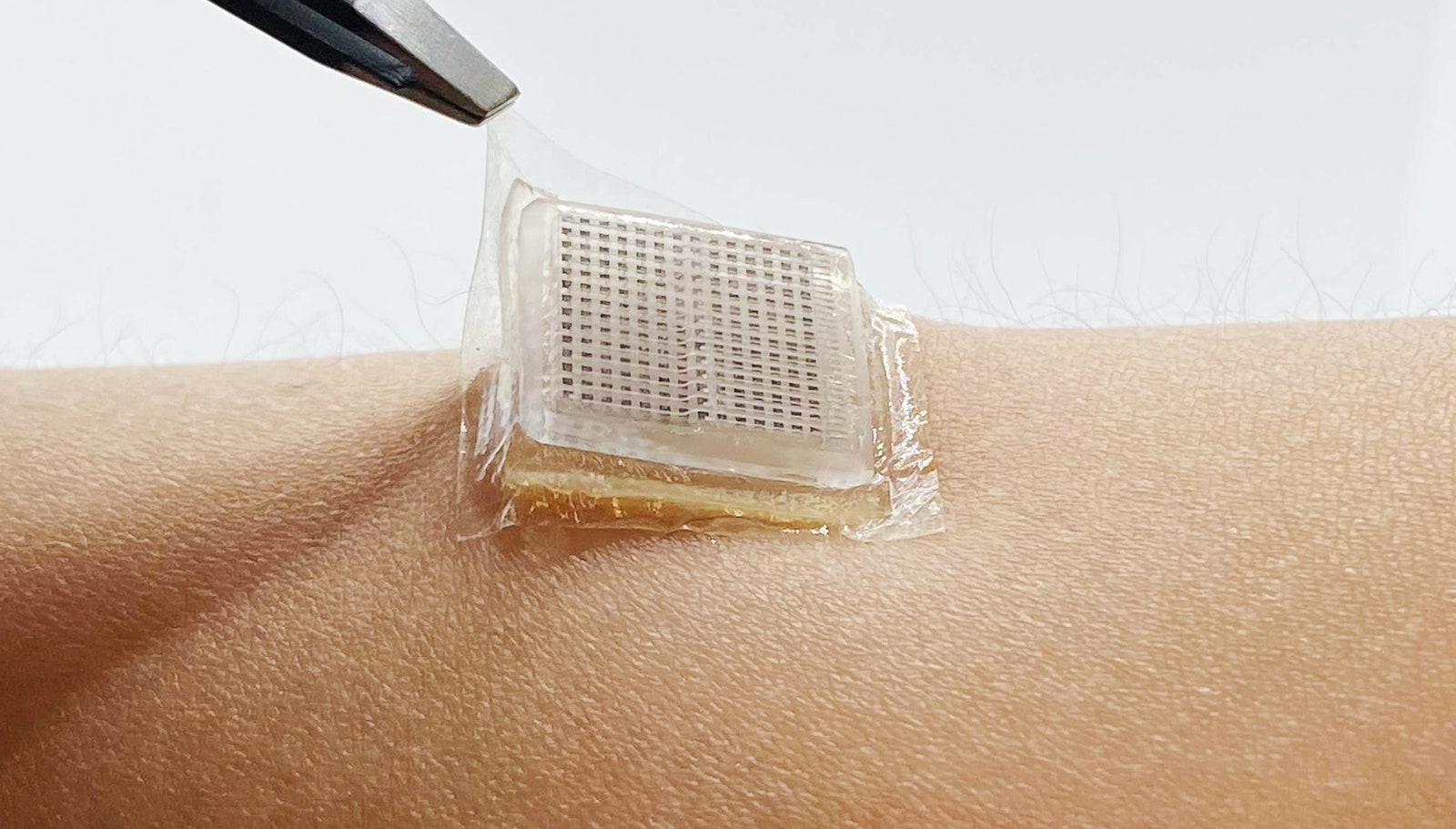

Although ultrasound technology is a staple in many medical facilities, it is often large and bulky. According to Xuanhe Zhao, a mechanical engineer at the Massachusetts Institute of Technology, the goal is to simplify and simplify everything and make it wearable. In the newspaper published today ScienceZhao and his team describe their development of a tiny ultrasound patch that can provide high-resolution images when attached to the skin. The scientists hope the technology could lead to ultrasound for long-term follow-up, perhaps at home rather than in the doctor’s office.

Because ultrasound equipment is so large and requires an office visit, Zhao said, imaging capabilities are often “short for a few seconds,” limiting the ability to see how organs change over time. For example, physicians may want to see how the lungs change after taking medication or exercising, which is difficult to achieve in an office visit. To overcome these problems, the scientists designed a patch approximately 1 square inch wide and a few millimeters thick that can be placed anywhere on the body and worn for two days. “It looks like a postage stamp,” says Zhao.

The adhesive is multilayered, like a candy wafer, with two main parts: an ultrasound probe mounted on a cupplant, a material that helps transmit sound waves from the probe into the body. The scientists made the probe thin and rigid using a 2D array of piezoelectric elements (or transducers) sandwiched between two circuits. Chongge Wang, one of the researchers involved in the study, said that these substances can convert electrical energy into mechanical vibrations. These vibrations enter the body as waves and are returned to the external imaging system to be translated into an image. Those vibrations, Wang added, are “completely non-invasive.” Humans cannot feel them at all.

The scientists used 3D printing, laser micromachining and photolithography to create the ultrasound probe; In this way, light is used to create a pattern on a photosensitive material. Then the probe is coated with an epoxy layer that helps protect it from water damage like sweat. These techniques are so efficient that scientists say a device can be manufactured in roughly two minutes.

A jelly-like coupling layer helps those ultrasound waves penetrate the body. It contains a hydrogen layer protected by a polyurethane layer to hold in water. All of this is coated with a thin polymer compound that acts like a strong glue to help the whole thing stick. The scientists found that the patch can remain attached to the skin for at least 48 hours, can be removed without leaving a residue, and is water resistant.

The MIT team is one of a small group of laboratories that have developed similar miniaturized ultrasound devices in the past few years. Labs at UC San Diego and the University of Toronto are working on related projects — Wang developed an earlier patch model at UCSD. But these were often limited in their imaging capabilities or larger than the size of a postage-stamp.

[ad_2]

Source link