[ad_1]

Canada-based RockTech Lithium will supply Mercedes-Benz with battery-grade lithium hydroxide (LiOH) by 2026 (from inauguration) of its lithium conversion plant in Guben, Germany ( previous post ). . Lithium hydroxide monohydrate (LiOH⋅H2O) It is an important prerequisite for the production of lithium-ion battery cathode material.

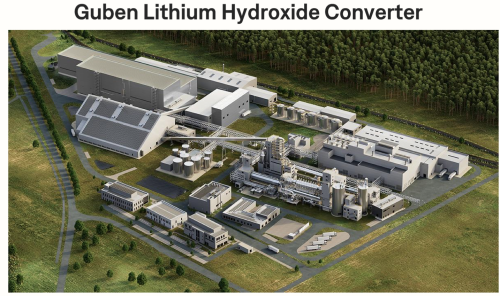

The Guben converter will have a capacity of 24,000tpa—enough to support about 500,000 EVs.

The two companies signed an agreement last year to supply Mercedes-Benz Battery Partners with high-grade lithium hydroxide refined at the new RockTech plant for 150,000 fully electric vehicles. (Previous post.)

The strategic partnership between Mercedes-Benz and RockTech began in 2011. It was announced following the signing of a memorandum of understanding between Mercedes-Benz AG and Canada at the German-Canadian summit in Toronto in late August 2022. Focusing on natural resource development paves the way for deeper collaboration at all levels of the automotive value chain.

Under the supply agreement, the two companies will collaborate to create a roadmap to achieve net carbon-neutral lithium hydroxide production by the end of 2030. In addition, the lithium hydroxide supplied by RockTech must be sourced from mine sites audited by the Respondents Initiative. Mineral Assurance (IRMA).

Mercedes-Benz is intensifying the vertical integration of fuel technologies in Germany and Europe:

-

The Mercedes-Benz battery plants in Untertuerkheim (Heidelfingen and Brühel), Kamenz and Jawor (Poland) and the announced sites in Sindelfingen and Koelda will play a key role in the company’s EV ramp-up.

-

Battery cells are supplied by European Automotive Cells Company (ACCC) factories. Mercedes-Benz AG has taken an equal stake in ACC along with Stellants and Total Energies, aiming to build a European battery champion with global ambitions. Battery cells are produced in three locations in Europe: Douvrain, Kaiserslautern and Termoli (Link).

-

At the heart of the Untertuerkheim plant, Mercedes-Benz is building an eCampus as a competence center for research and development of new battery and battery cell generations.

-

The plants in Untertuerkheim and Sebes (Romania) will produce electric drive units for new MMA and MB.EA platform models from 2024.

-

The Mercedes-Benz plant in Berlin has been producing high-performance electric motors for the future AMG.EA platform since the middle of the decade.

[ad_2]

Source link