[ad_1]

Software product managers have the most thankless job—knowing which features to push into development, what developers prioritize to work on, and gathering requirements from internal teams, external customers, and what the company uses in its marketing materials. – It’s an endless game of reasoning and matching. As hard as that job is, at least software PMs have a software stack to help them do their job. If you’re working in hardware development, there aren’t many options for collaboration—at least until Five Flute comes along.

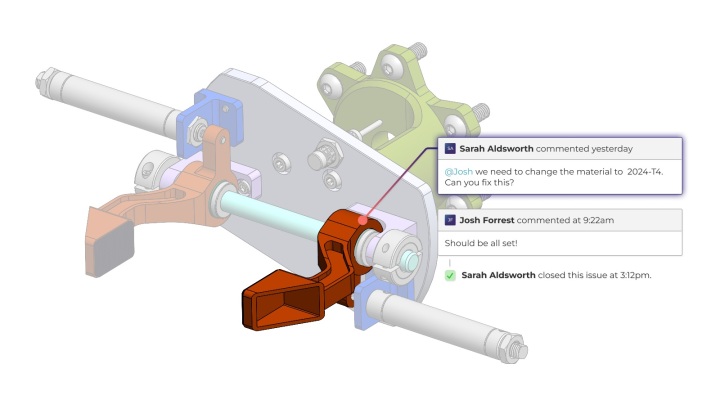

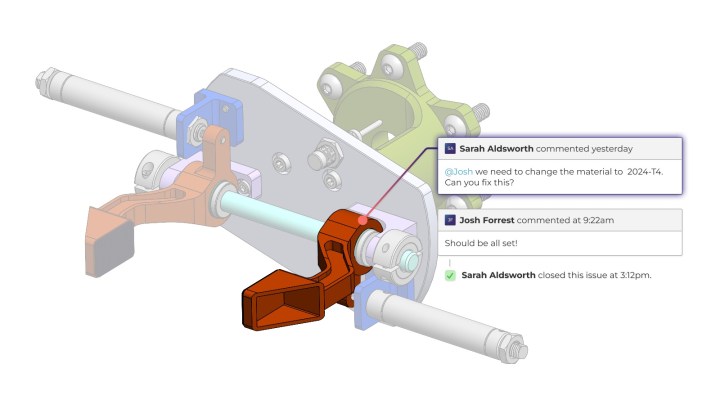

In short, Five Flute is an issue tracking platform for anyone developing physical products. I spoke with the company’s CEO, and (spoiler alert!) you can see the company’s entire working floor as part of Thursday’s episode of my Pitch Deck Breakdown series.

“When we released the web version of Five Flute last year, we started getting questions from our users about how to interface with CAD. We saw firsthand that mechanical engineers and industrial designers wanted more collaboration and visual communication capabilities directly in CAD,” said William Burke, founder and CEO of Five Flute, of the SolidWorks plugin. said the startup. “Engineers don’t want to go into a separate web app, find the right project, and then define complex engineering issues in a place completely disconnected from the design’s source of truth. We’ve heard stories of frustrated engineers on teams split between Asana, PowerPoint design logs, and Post-it notes, which There is no clear way to determine whether design feedback is implemented at the part and assembly level.

Today, the company has raised $1.2 million in SAFE notes, led by Baukunst, Fenton Founders Fund, Christian Thönes (CEO of metal manufacturing company DMG Mori), Andy Palmer of Koa Labs and others. The investment is particularly noteworthy given that Baukunst Investments-led Axel Bichara was one of the first investors in SolidWorks, today one of the industry standards for computer-aided design and manufacturing (CAD/CAM), and joins other investments in the CAD space (the investments include Join, which recently announced a $16 million round include early cash).

“With the rise of connected devices, physical product development has become increasingly multidisciplinary. Mechanical engineers, electrical engineers and industrial designers are spending more time working in siloed, discipline-specific desktop applications than in multi-player products,” Burke said. It allows them to seamlessly collaborate on engineering issues without leaving the 3D design programs they already work in.”

Five Flute plans to invest the cash flow to expand its engineering team and growth marketing efforts. Over the next 18 months or so, the company is putting all its product-eggs in the problem-tracking platform basket.

“THe is most recently focused on building our core issue tracking platform and small CAD integrations. We have several collaboration features that help engineers quickly identify and solve problems; Engineering managers are providing more visibility into team development than ever before,” said Burke. “For engineering technicians, assemblers and manufacturing engineers, five flutes allow them to quickly connect prototypes and early production parts to their resulting cases. For technical program managers and hardware leadership, this means their design and manufacturing engineering teams can find and solve more issues every time, helping them deliver more functional products in less time.

The company’s ultimate goal is to make Five Flute the default collaboration platform for developing physical products. “Everything from Chan to satellite launch and everything in between,” laughs Burke.

The company name itself is a wonderful nod to the prototyping process. The cutting edge of the mill (used to process the metal blocks) is called a “flute” and high speed and precision milling tools come in any number, and machinists will spend days on the right tool. The right material. As an amateur metalworker myself, it makes me smile – and if you can name your company’s prototyping engineers something they know and remember, why not!

[ad_2]

Source link