[ad_1]

The COVID-19 pandemic has disrupted work in almost all sectors and manufacturing has not been immune to this development. The sector is recovering gradually but a positive development is the increasing use of innovation.

There have been many innovative trends in the manufacturing sector that promise to help the sector do well. These trends are being followed by many trends and if you are in this sector, it is time to consider adopting these trends.

We present six such innovative trends in manufacturing.

6 Innovative Manufacturing Trends

1. IoT

IoT or the Internet of Things is one of the most innovative trends in all sectors. Even in the manufacturing sector, IoT offers great benefits for companies. IoT is all about interconnecting various devices with a company through the internet. It is essentially all about using smart devices that are connected to each other. There are many companies that use smart devices on the production floor.

These devices not only help in improved production but also make the production facility safe for workers. IoT offers an exciting opportunity for manufacturing firms to incorporate technology in their process and their product. IoT allows for remote monitoring and even maintenance of equipment and machinery.

With so many benefits, it is no wonder that IoT is the top innovative trend for manufacturing.

2. Predictive Maintenance

Preventive maintenance is common but predictive maintenance is the trend today. Studies reveal that just one hour of breakdown leading to downtime can cause losses of more than $ 100,000. To prevent downtime, the use of predictive analytics can help. This is a latest innovative trend where analytics is used to try and predict when the performance of equipment can fail.

Based on this analysis, the equipment can be subject to maintenance. This not only prevents downtime but can extend the life of equipment. This is one trend that can save a lot of money and problems for this sector.

3. 3D Printing

3D printing is an innovative trend that is fast catching on. The process of creating tools used to previously take many months. This would affect production schedules and work in general.

Thanks to 3D printing, tools can be designed in the factory and produced using a 3D printer. This speeds up production schedules and can be very helpful. Manufacturing concerns in the automotive and aerospace sectors have been using 3D printing in a big way. It won’t be long before it catches on in other sectors.

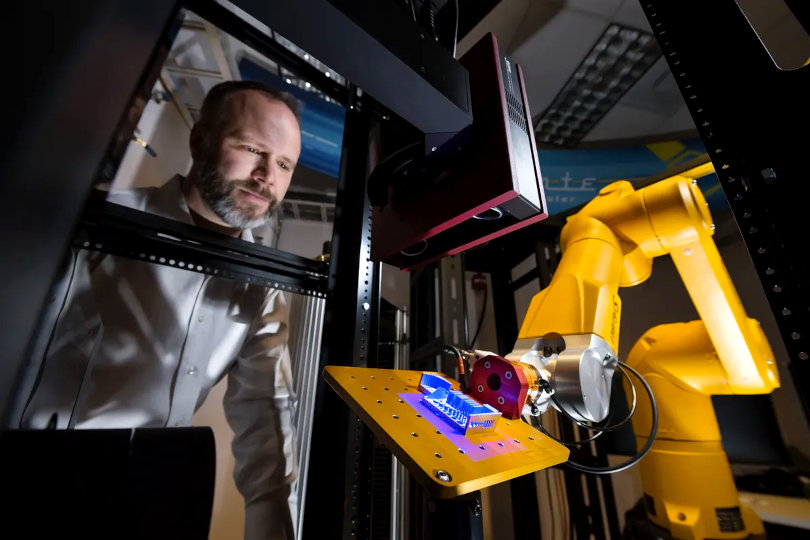

4. Robotics

With the increased difficulty in finding the right persons for the job and in retaining them, robotics presents an attractive option for companies. Robotics helps deal with problems related to labor shortage. It also helps in automating repetitive tasks and tasks that call for higher accuracy.

New advances in the field of robotics have ensured that even smaller firms can get robots to make their work easier. From welding to painting, and assembling to inspection there is no activity that robots can’t do. This is going to be one of the key trends for the future.

5. Cloud Computing

Cloud computing has already made its mark in the world of Information Technology. Manufacturing companies can also benefit from cloud computing.

Using this innovative technology allows a company to link together various plants and offices. It allows them to share data easily and quickly. This helps in improving productivity and reduces time. Cloud computing can be used in different areas of manufacturing right from design to supply chain management.

6. VR and AR

Virtual Reality and Augmented Reality were once seen as technologies aimed at the gaming and entertainment sectors. Today VR and AR are benefiting manufacturing companies in a big way. VR and AR devices can be used on the production floor and can be very helpful in improving workplace safety. A person wearing a VR device would be able to read the temperature of equipment without coming in contact with it. This can prevent potential risks.

To Conclude…

During the pandemic, it has helped technicians solve problems without coming into physical contact with customers. It can be very helpful in carrying out troubleshooting activities from remote. Customers can also be given these devices making them self-sufficient in solving problems with remote assistance. This is an innovative trend that promotes safety.

[ad_2]

Source link